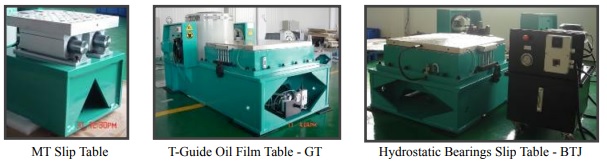

MT & T-Guide Oil Film Slip Table & Hydrostatic Bearings Slip Table

Typical System Application![]() The Slip Table caters to horizontal vibration testing even during production line type application. It is ideally suited for a sequential 3-axis test. There are four kinds of slip tables in guidance method of using Mechanical linear bearings (MT), T guide (GT, instead of conventional V guide), hydrostatic journal bearings (BTJ) and hydrostatic T shape bearings (BTT).

The Slip Table caters to horizontal vibration testing even during production line type application. It is ideally suited for a sequential 3-axis test. There are four kinds of slip tables in guidance method of using Mechanical linear bearings (MT), T guide (GT, instead of conventional V guide), hydrostatic journal bearings (BTJ) and hydrostatic T shape bearings (BTT).

Most of the slip tables are configured with Centering Back System (CBS) to cause the table to return to the natural center during vibration.

Features

Integrated and Combo Design

The slip table is integrated to the shaker by "combo" base designs. This feature results in permanent and easy repeating alignment, long term reliability & durability, performance, structural integrity and simple operation.

Convenient Operating

A unique trunnion and guidance bearing assembly provides simple shaker rotation capability and body vibration isolation. The electrodynamic shaker can be rotated to the vertical position for one axis and then to the horizontal position where it is connected to a horizontal slip plate for the other two axes testing.

Mechanical linear bearings Guide Slip Tables - MT Series

Smaller slip tables, up to 400mmX400mm, use mechanical linear bearings instead of oil film to make the system more compact and easy to maintain.

T-Guide Oil Film Slip Tables - GT Series

T-Guide Oil-Film Slip Tables are designed with precision granite and are combined with a magnesium or high-grade aluminium slip plate to provide the most cost-effective way to perform general horizontal testing. The slip plate is guided by T-Shape Oil-Film guides by one or two more located front and back base to provide high restraint during high moment operations. The conventional V-shape can be replaced by this T-Shape guide directly.

Hydrostatic Journal Bearings Oil Film Slip Tables - BTJ Series

Hydrostatic Journal Bearing Slip Tables are designed for high over-turning moment and cross axial restraint. The design combines magnesium or high grade aluminium slip plate, precision flat granite and hydrostatic journal bearings applied by 17.5 Mpa high pressure oil to provide a very high dynamic moment restraint while preserving the damping characteristics of the oil film. This system allows testing of heavy products with high centers of gravity by reacting moments through the hydrostatic bearings. Multiple bearings can be configured to restrain huge over turning moments.

Hydrostatic T Shape Bearings Oil Film Slip Tables - BTT Series

This slip table applies medium oil pressure of 10 Mpa to T shape hydrostatic bearings. Normally, the T shape bearings are arranged in matrix to anchor and hold the slip plate in matrix points to prevent the deformation in bending. Customized distribution of the T shape bearings can fasten the circle type fixture for standing cylinder object horizontal testing more robustly. This supplying will be discussed case by case.

Magnesium Head Expander

Features

The Magnesium Head Expander provides vertical test mounting surface larger than the one the shaker armature provides. It is fabricated with casting ZM5 (equivalent to AZ91) with top and bottom surface flatness and parallelism greater than 0.15mm. To protect the magnesium, all the bases of bolt counter bore holes are fitted with thick stainless steel washers, pressed into place. To prevent oxidation, the head expander’s surface is anodized. Stainless inserts are used for the specimen mounting.

The magnesium has the characteristics of high specific stiffness and specific strength which prove singularly useful for fabricating the shaker head expander.

Due to the design of FEMA (Finite Element and Modal Analysis), the head expander can achieve higher useable frequency with low mass to make the shaker output force effective.

There are three kinds of top surface namely, octagon, round and square. Due to the flapping of the 4 corners of the square top surface, the 4 corners are cut resulting in an octagon shape to achieve higher uniformity.

Aluminum Alloy is also used to fabricate the head expander in case the testing needs higher useable frequency and the higher driven mass of the head expander is not a critical factor.

The useable frequency means the max controllable frequency when the control point is located at the center and transferring shaker’s rated force. The controllable frequency depends on the location of the control point and force.