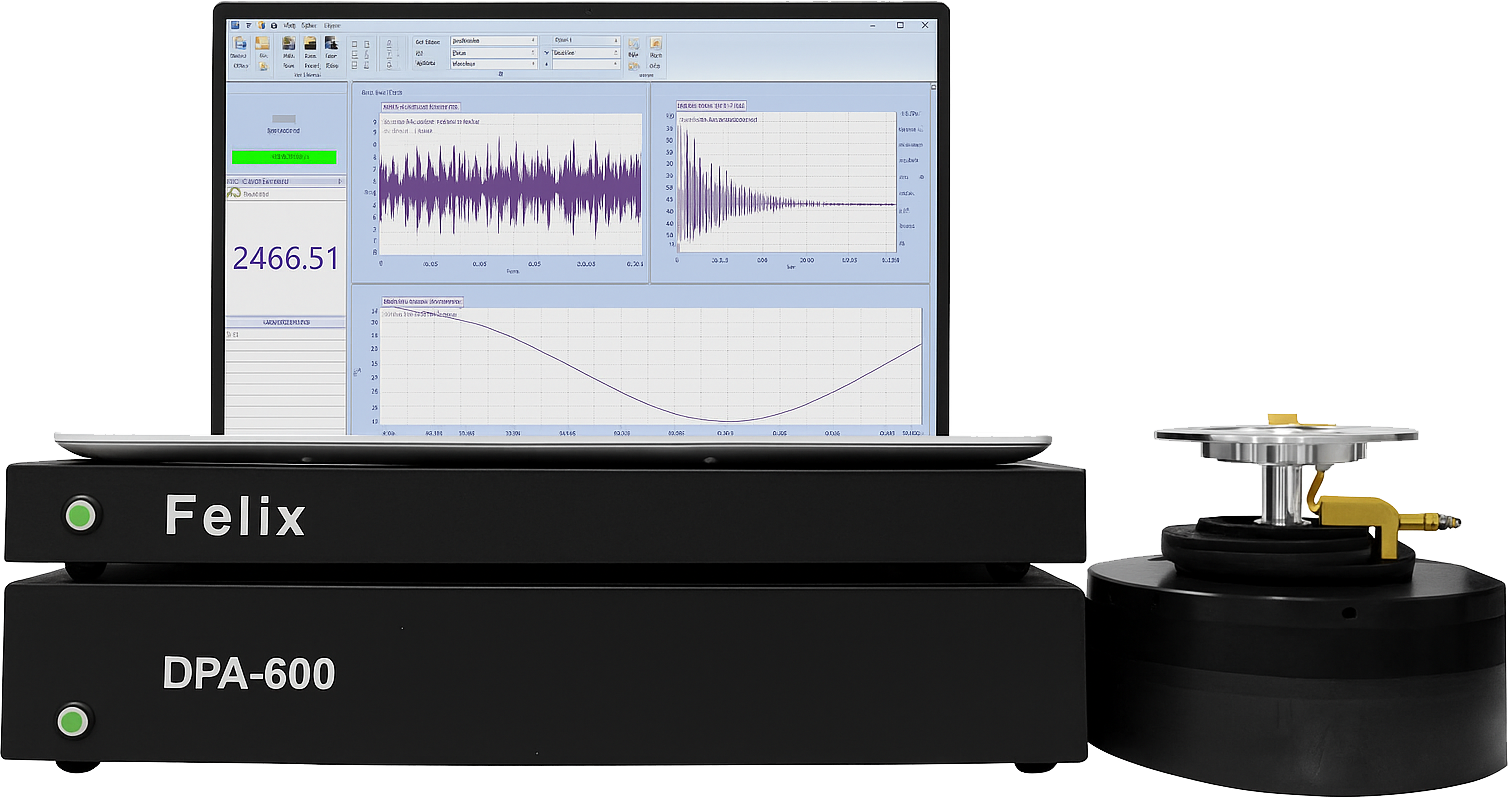

Our non-destructive high frequency acoustic test monitors for loose particles moving inside high reliability internal cavity electronic components such as relays, transistors, hybrids, integrated circuits, and switches – particles that have the potential of causing short circuits and serious malfunctions in system operations. A shaker is used as a linear motor to excite loose particles to move within the component cavity. Upon striking the lid of the cavity, some of the particle kinetic energy (½mv2) is converted to a wide band acoustic pressure wave that travels through the lid, through the attachment media, and onto the top surface of the Impact Detection Sensor. The acoustic wave is detected by the sensitive ultrasonic crystal or crystals within the sensor and converted to an electrical signal. To keep the particle moving, a very accurate shock, generated internal to the shaker and controlled by the computer, monitoring the motion of the sensor, is employed.