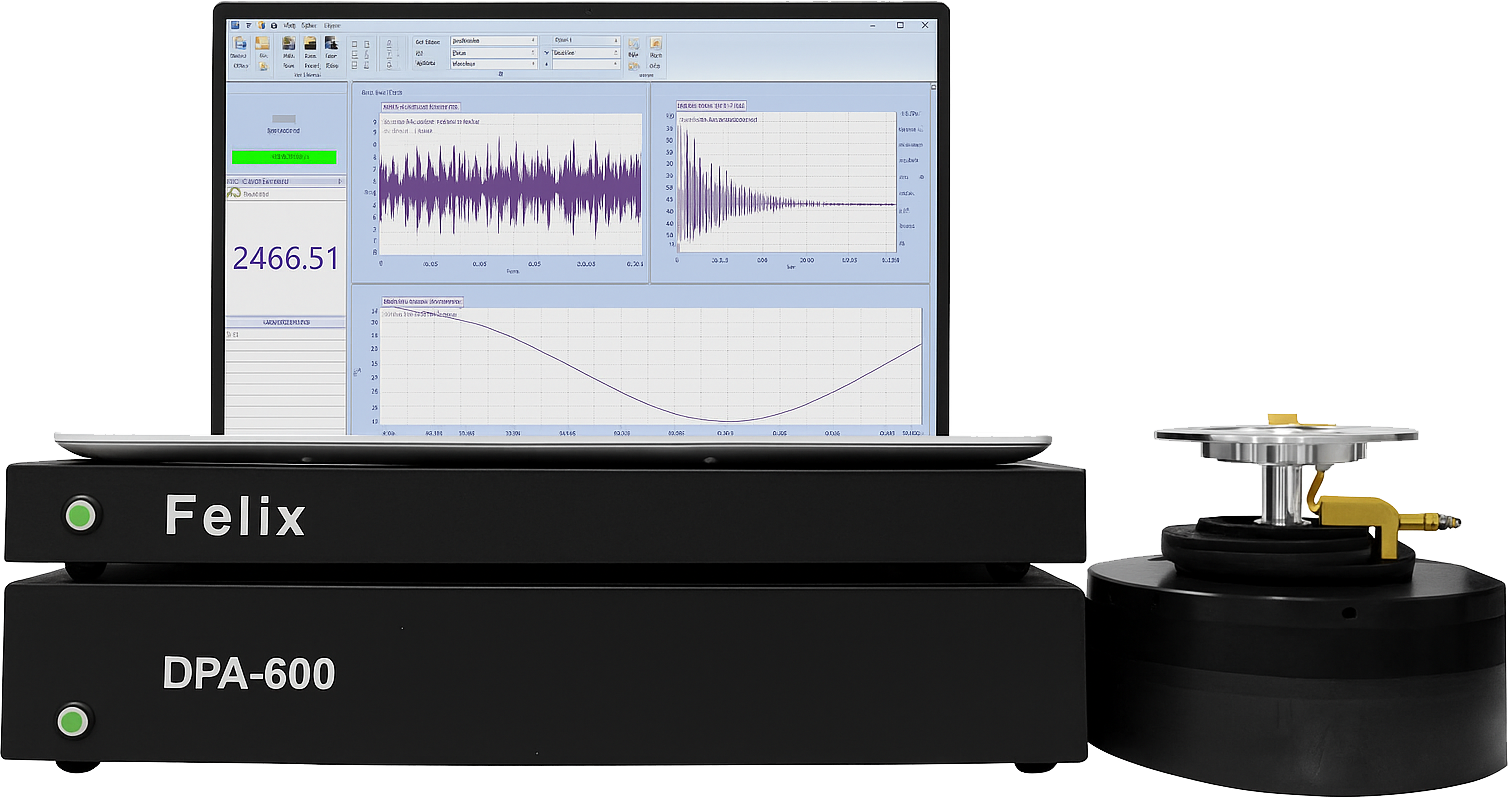

The high-speed Acoustic channel has a center frequency of 155 KHz to minimize noise and maximize signal. The amplification is set to 60dB and the precision fixed anti-aliasing filters are set so the 8X oversampling produces a bandwidth of over 2MHz. Further filtering used to limit the frequency of interest to the peak sensitivity of the sensor. The tiny signals created by the crystal are increased in size to be digitized without aliasing and the data is sent to the onboard Computer System on Module (SOM).

The vibration channel features an advanced charge amplifier again with powerful anti-aliasing filters to deliver preprocessed data to the SOM for decimation and filtering down to 20KHz and converted to the frequency domain as well as the time domain.

In a separate shock channel, the output from the measuring sensor is processed with anti-aliasing protection down to 50KHz. Finally, the fourth channel is designed as expansion and could be used to monitor the output current of the unique differential digital 600-Watt Power amplifier so that the current into the shaker can be compared to the motion measured by the sensor for the health and maintenance of the system. Motion is generated by the digital output channel with full anti-imaging filters which feeds the Digital Power Amplifier to generate both the vibration and the shock excitation. Yes, the shock is also computer generated!

In the PIND Test, the particles are never measured directly. We put loose particles in motion with a vibration, shock, and then detect the impacts of those particles as they contact the lid of the cavity.