SHOCK

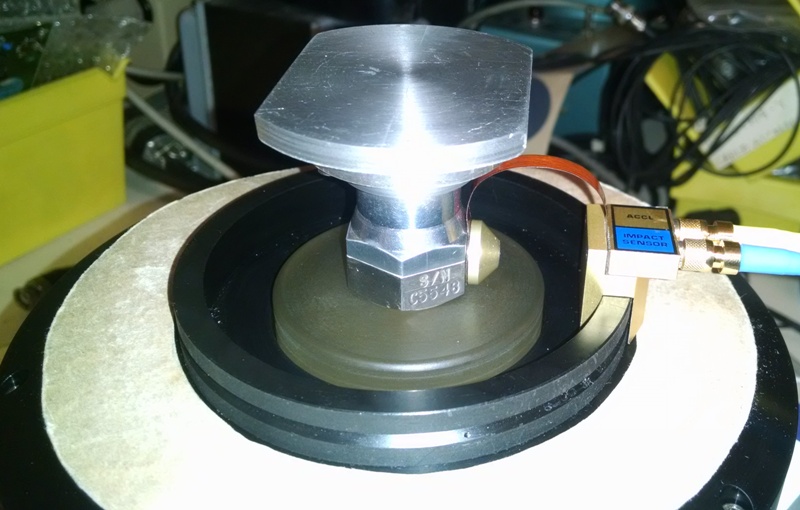

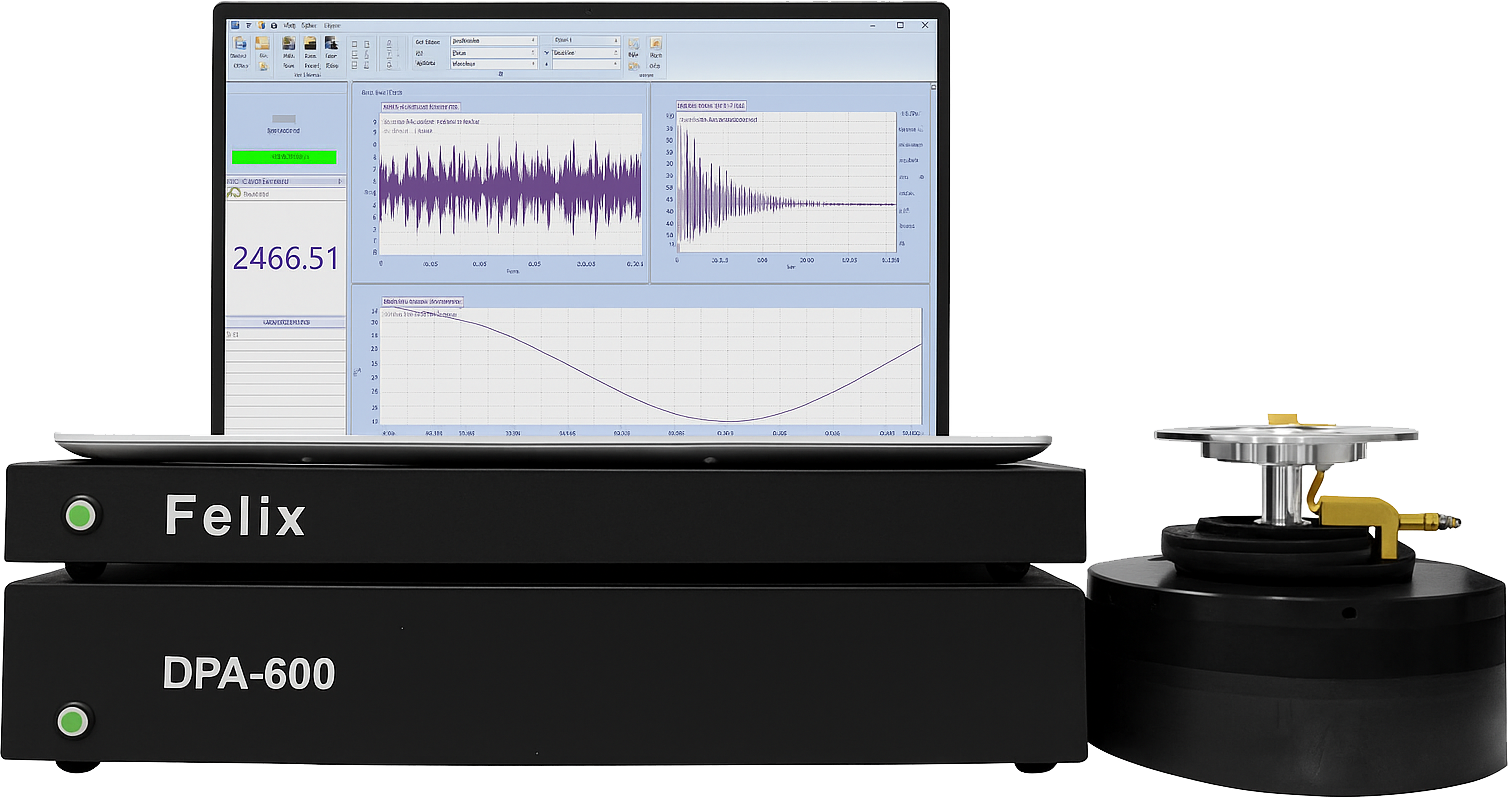

The shock is used in the PIND test to free particles that adhere to the cavity wall. The smaller particles are more prone to exhibit the property of adhesion and stop moving during the vibration cycle. The shock amplitude must be held to within 20%. Unique to the SD PIND system is an “Active Shock”. The computer controls of the shaker motion which is active during the shock until the striker in the armature collides with the shock anvil deep inside the shaker. The shock is created by the stopping of the armature velocity creating

a dynamic shock pulse that travels up the sensor to the DUT. The computer control allows a programming change to shock amplitude to accommodate the larger loads. Older mechanical shocks using a spring-loaded tapper actuated shock must be reset by manually adjusting the screws for any parts that weigh over 25 grams. The SD PIND shock is calibrated and programmable from 500 to 1500 g’s and the display reads the calibrated value of the shock waveform during the test for the actual DUT. In addition there is a selectable boost for heavier parts or a negative boost to get lower values than the calibration range. In this way the dynamic conditions are always monitored and accurate throughout the variety of test conditions and devices being tested.

Vibration & Shock

VIBRATION

The particles are put into motion by vibrating the electronic component on top of the shaker at a fixed frequency. The accuracy of the shaker motion is required to be within 10%. For the Heavy Duty M230 shaker, with the larger 100-5S155-4 multiple crystal sensor the capacity is within tolerance at 130 Hz to above 400 grams.